Hot-selling Magnet Socket - 2100KG,2500KG Pulling Force Precast Concrete Magnet Assembly for Steel Formwork or Plywood Mould Fixing – Meiko

Short Description:

Hot-selling Magnet Socket - 2100KG,2500KG Pulling Force Precast Concrete Magnet Assembly for Steel Formwork or Plywood Mould Fixing – Meiko Detail:

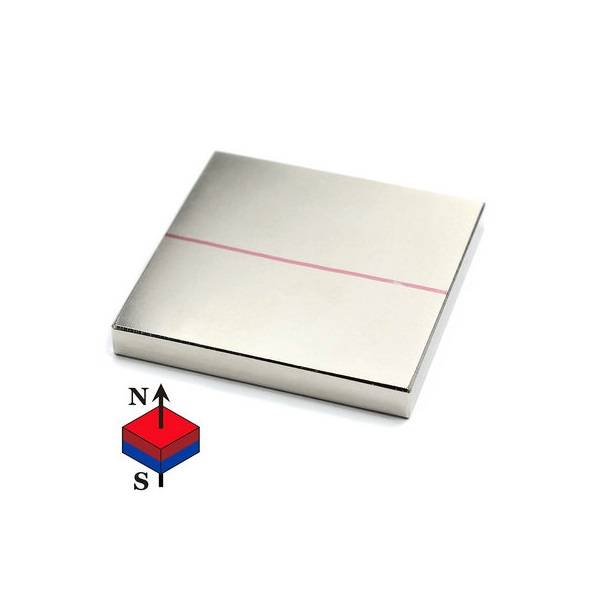

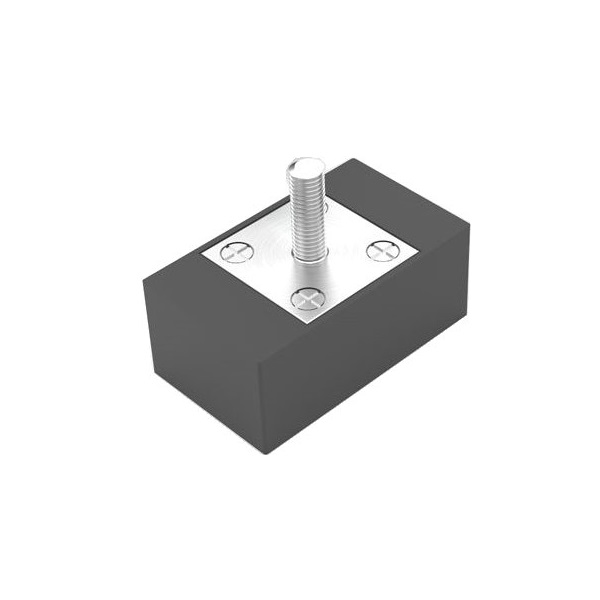

2100KG Precast Concrete Magnet is a standard power capacity type for shuttering magnets, which is highly recommended to use for fixing sidemould in precast concrete sandwich panels. It can fits well on steel formwork or wooden plywood formwork, with different adaptors. The picture showed is a fixture connecting with wooden or plywood side-mold.

After button pressed, the box magnets hold the table firmly. It’s easy to nail the steel plate on the wooden plate with nails.It can be activated by simply pressing down the button by the hand or foot. To deactivate them, the magnets are easily released by steel lever (to pull the button on). In the inactive position, the shuttering magnets can be easily removed from the table form. The precast concrete magnets could be used alone or connected with adpator to fix the formwork. Normally 2100Kg vertical force box magnet is perfectly suitable for 60-90mm thickness wall panel production. Also, we are able to manfuacture other power foce box magnets, even as 2500KG, 3000KG type as your demands.

KEY BENEFITS OF Precast Shuttering Magnet:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce radial products. Formwork Shuttering Magnet for Precast Plant

5. A small cost of a set of magnets. The average payback of about 3 months.

6. The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table. Precast Concrete Shuttering Magnet Box 900kg

| Type | L | W | H | Screw | Force | N.W. |

| mm | mm | mm | KG | KG | ||

| SM-450 | 170 | 60 | 40 | M12 | 450 | 1.8 |

| SM-600 | 170 | 60 | 40 | M12 | 600 | 2.3 |

| SM-900 | 280 | 60 | 40 | M12 | 900 | 3.0 |

| SM-1350 | 320 | 90 | 60 | M16 | 1350 | 6.5 |

| SM-1800 | 320 | 120 | 60 | M16 | 1800 | 7.2 |

| SM-2100 | 320 | 120 | 60 | M16 | 2100 | 7.5 |

| SM-2500 | 320 | 120 | 60 | M16 | 2500 | 7.8 |

We, Meiko Magnetics, are professional in all kinds of magnetic solutions for precast concrete industry. You can find all your standard requirements or customized magnetic system here for precast.

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Hot-selling Magnet Socket - 2100KG,2500KG Pulling Force Precast Concrete Magnet Assembly for Steel Formwork or Plywood Mould Fixing – Meiko, The product will supply to all over the world, such as: New Zealand, Morocco, Lebanon, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.