Manufacturing Companies for Drilling Neodymium Magnets - Ring Neodymium Magnets with Nickle Plating – Meiko

Short Description:

Manufacturing Companies for Drilling Neodymium Magnets - Ring Neodymium Magnets with Nickle Plating – Meiko Detail:

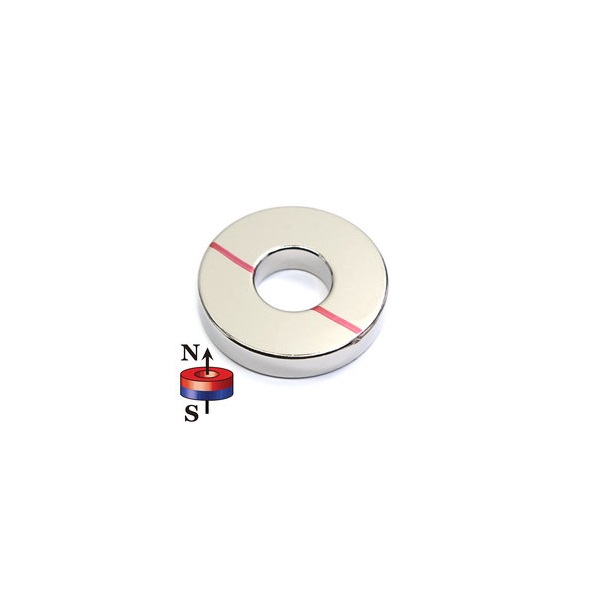

Neodymium Ring Magnet with NiCuNi Coating are the disc magnets or cylinder magnets with centered straight hole. It’s widely applied for motors assemblies, economics, like plastic mounting parts for providing constant magnetic force, due to the characteristic of permanent rare earth magnets. Such electronic magnet processes higher magnetic performance than Hard Ferrite used in electronic magnets with much smaller size.Meanwhile,this kind of neo magnet has advantage of high precision,which can improve the electronics performance. Sintered Neodymium(NdFeB) magnets are the most advanced commercialized permanent magnet materials today.

The N pole is marked with red line for workers’ easy assembling, no more attention to paid on the poles of magnet, which side is N, which side is S pole, as the wrong pole installing in the processing will cause the assembling components can’t work.

Features

1. Materials:Neodymium-Iron-Boron;

2. Grades:N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH and 30EH-35EH;

3. Shapes and sizes: according to customers’ request;

4. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;.

5. Applications:sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on;

6. Utilizations of new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

7. High coercive force, the max operation temp is up to 200 degree centigrade or 380 curie temperature

Product detail pictures:

Related Product Guide:

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for Manufacturing Companies for Drilling Neodymium Magnets - Ring Neodymium Magnets with Nickle Plating – Meiko, The product will supply to all over the world, such as: Bulgaria, Holland, Vancouver, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.