OEM/ODM Supplier Wire Box Magnet - 1350KG, 1500KG Type of Magnetic Formwork System – Meiko

Short Description:

OEM/ODM Supplier Wire Box Magnet - 1350KG, 1500KG Type of Magnetic Formwork System – Meiko Detail:

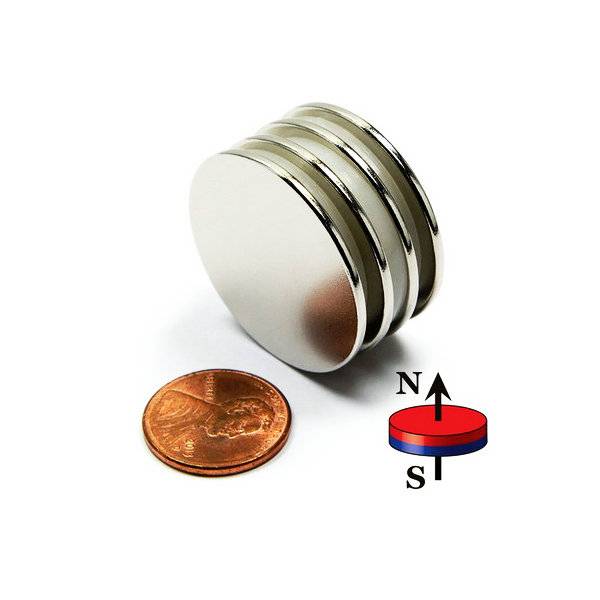

1350KG or 1500KG Magnetic Formwork System is also a standard power capacity type for precast concrete plateform fixing, which is highly recommended to use for fixing sidemould in precast concrete sandwich panels. It can fits well on steel formwork or wooden plywood formwork, with different adaptors or pressing bolts.

After button pressed, the box magnets hold the table firmly. It’s easy to nail the steel plate on the wooden plate with nails.It can be activated by simply pressing down the button by the hand or foot. To deactivate them, the magnets are easily released by steel lever (to pull the button on). In the inactive position, the shuttering magnets can be easily removed from the table form. The precast concrete magnets could be used alone or connected with adpator to fix the formwork. Normally 1350Kg vertical force box magnet is perfectly suitable for 80-150mm thickness wall panel production. Also, we are able to manfuacture other power foce box magnets, even as 2500KG, 3000KG type as your demands.

Due to our rich experiences on precast concrete projects’ following, we, Meiko Magnetics, are capable of designing and producing all sized magnetic solutions for precast concrete elements factory, no matter box magnets, inserted magnets, pipe magnets, magnetic recess former or other magnetic systems in precast applications.

KEY BENEFITS OF Precast Shuttering Magnet:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce radial products. Formwork Shuttering Magnet for Precast Plant

5. A small cost of a set of magnets. The average payback of about 3 months.

6. The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table. Precast Concrete Shuttering Magnet Box 900kg

| Type | L | W | H | Screw | Force | N.W. |

| mm | mm | mm | KG | KG | ||

| SM-450 | 170 | 60 | 40 | M12 | 450 | 1.8 |

| SM-600 | 170 | 60 | 40 | M12 | 600 | 2.3 |

| SM-900 | 280 | 60 | 40 | M12 | 900 | 3.0 |

| SM-1350 | 320 | 90 | 60 | M16 | 1350 | 6.5 |

| SM-1800 | 320 | 120 | 60 | M16 | 1800 | 7.2 |

| SM-2100 | 320 | 120 | 60 | M16 | 2100 | 7.5 |

| SM-2500 | 320 | 120 | 60 | M16 | 2500 | 7.8 |

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for OEM/ODM Supplier Wire Box Magnet - 1350KG, 1500KG Type of Magnetic Formwork System – Meiko, The product will supply to all over the world, such as: Czech republic, Vietnam, Istanbul, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!